Equipped with high resolution inspection ability.Install unique light source for Pellicle inspection sytem.Can inspect min. 0.5um defect/scratch.

The system can inspect various types of graphics, whether simple or complex, and can provide comprehensive inspection capabilities to ensure the accuracy and completeness of detection.

The automated feeding/discharging system effectively reduces personnel's direct contact with the photomask, reduces the risk of contamination and damage, and improves operating efficiency and product quality.

Each layer(photomask/pellicle) needs to be inspected separately. To ensure each layer can meet the standard.

Equipped with a high-efficiency particulate air filter (HEPA), which can filter out 99.97% of tiny particles, providing a clean operating environment, further reducing the risk of contamination and ensuring product stability.

The light source specially designed for Pellicle defect detection provides stable and high-brightness lighting to ensure the accuracy and reliability of detection results.

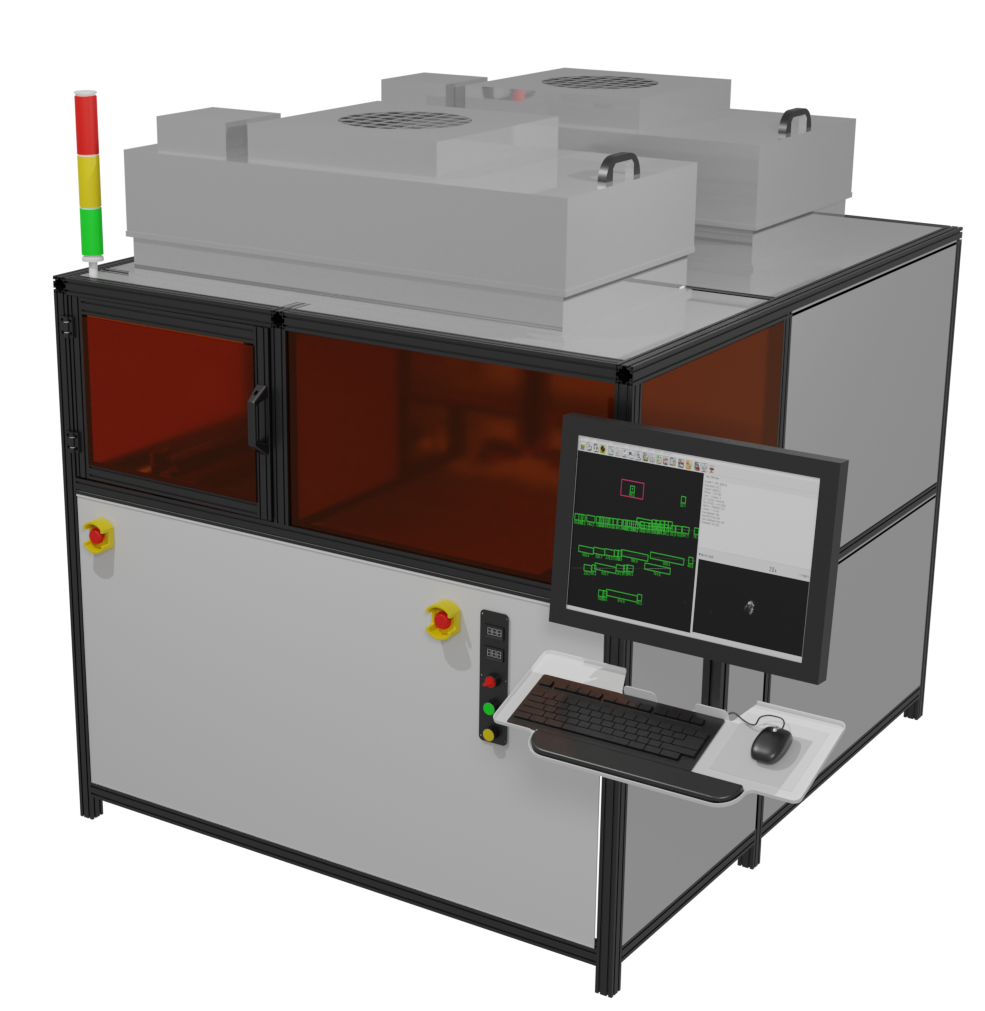

The integrated design of the main machine + box opening system + automatic feeding and discharging system of this product covers an overall area of only 1350 x 2150 x 1800 mm. This design saves space in the factory and allows it to be deployed more flexibly in different production environments.